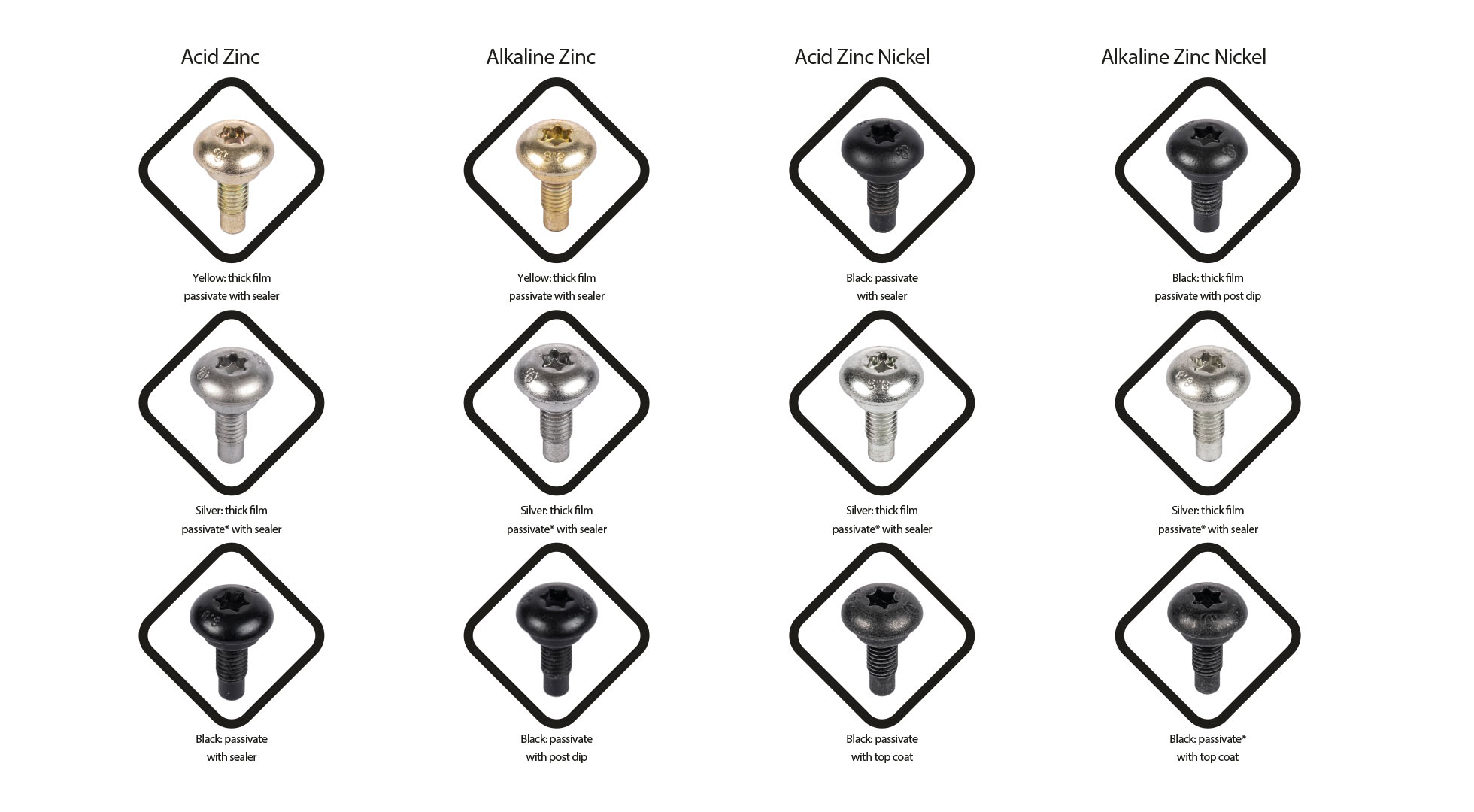

Zinc Coating

Adopting the principle of quality service, we perform surface treatment with alkaline zinc coating process in our automation-controlled electrolyzed coating line.

Our process has the ability to fully comply with customer specifications with yellow, white and black Cr+3 passivation, lacquer applications and hydrogen stress relief after coating.

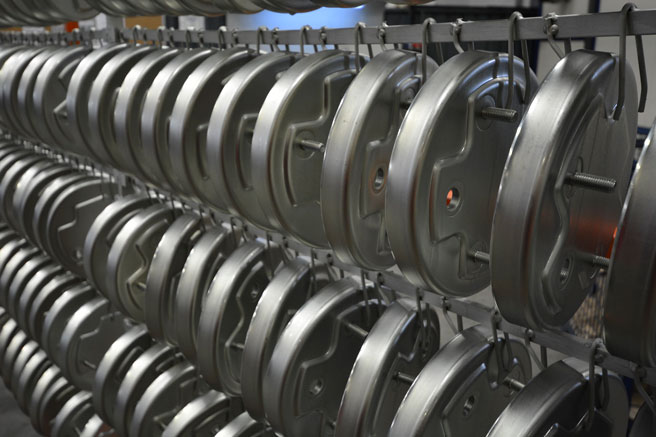

Our maintenance department can take quick action by making the hanger-apparatus production special for the product in our own facility and we achieve high coating quality with fully compatible apparatus.

By using the technology correctly, we define the most accurate recipes and operations for the products with our own software at the sample stage and ensure the continuity of the correct production.

We carry out traceable production with the same technology and convey product traceability to our customers.

Zinc Nickel Coating

Adopting the principle of quality service, we perform surface treatment with alkaline zinc nickel alloy coating process in our automation-controlled electrolyzed coating line.

Our process has the ability to fully comply with customer specifications with transparent, blue and black Cr+3 passivation, lacquer applications and hydrogen stress relief after coating.

Our maintenance department can take quick action by making the hanger-apparatus production special for the product in our own facility and we achieve high coating quality with fully compatible apparatus.

By using the technology correctly, we define the most accurate recipes and operations for the products with our own software at the sample stage and ensure the continuity of the correct production.

We carry out traceable production with the same technology and convey product traceability to our customers.

Adhesive Application

Adopting the principle of quality service, we apply two-layer paint to the surface prepared products with an automation-controlled conveyor paint machine.

After the products are ready for the process by degreasing and sandblasting, primer CHEMOSIL 211 and cover CHEMOSIL 411 are applied at appropriate temperature and pressure values.

Our process is implemented within the framework of full compliance with customer specifications and special requests.

Coating Types